Image Source: Google

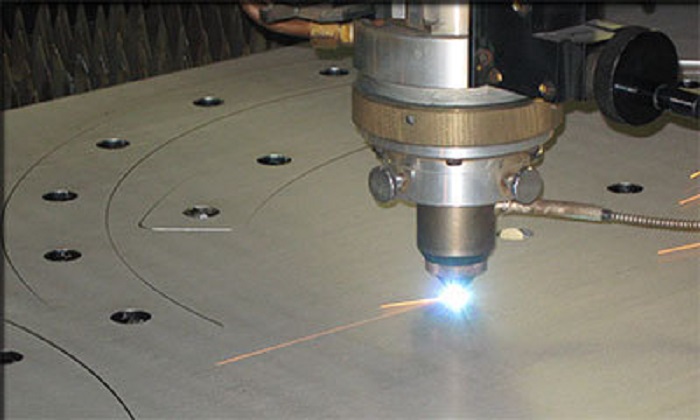

In today's fast-paced world, technology is constantly evolving and revolutionizing the way we do things. Laser manufacturing services are at the forefront of this technological revolution, offering precise and efficient solutions for a wide range of industries. From cutting and engraving to welding and marking, laser technology has become an indispensable tool in modern manufacturing processes.

The Basics of Laser Manufacturing Services

The best laser manufacturing services involve the use of high-powered lasers to cut, engrave, weld, or mark various materials with precision and accuracy. This technology has significantly improved manufacturing processes by offering several advantages over traditional methods, including:

- Precision: Laser technology allows for high levels of precision, making it ideal for intricate designs and complex patterns.

- Speed: Laser cutting and engraving are much faster than traditional methods, reducing production time and increasing efficiency.

- Versatility: Lasers can work with a wide range of materials, including metal, plastic, wood, and even glass, making them suitable for diverse applications.

- Quality: Laser manufacturing services produce high-quality results with clean edges and minimal waste, ensuring a superior finished product.

- Automation: Laser systems can be automated for continuous operation, reducing the need for manual labor and increasing productivity.

Applications of Laser Manufacturing Services

Laser technology is used across various industries for a wide range of applications. Some common applications of laser manufacturing services include:

1. Automotive Industry

- Laser welding for joining metal parts quickly and efficiently.

- Laser cutting for precision trimming of automotive components.

- Laser marking for labeling and branding automotive products.

2. Aerospace Industry

- Laser drilling for creating precise holes in aircraft components.

- Laser engraving for part identification and tracking.

- Laser cutting for trimming composite materials used in aircraft construction.

3. Electronics Industry

- Laser cutting for precise trimming of circuit boards and electronic components.

- Laser marking for labeling and branding electronic devices.

- Laser welding for joining delicate electronic components without heat damage.

The Future of Laser Manufacturing Services

As technology continues to advance, the future of laser manufacturing services looks promising. Some key trends and developments that are shaping the future of laser technology include:

1. Increased Automation

Automation plays a crucial role in the future of manufacturing, and laser technology is no exception. The integration of robotics and artificial intelligence has enabled the automation of laser systems, leading to increased efficiency and productivity.

2. Advancements in Materials Processing

Laser technology is constantly evolving to work with new and advanced materials. From carbon fiber composites to ceramics, lasers are being used to process a wide range of materials with precision and accuracy.

3. Integration of Additive Manufacturing

Combining laser technology with additive manufacturing processes like 3D printing is revolutionizing the production of complex parts and components. This integration allows for greater design freedom and customization in manufacturing processes.

4. Sustainability and Eco-Friendly Practices

With increasing focus on sustainability, laser manufacturing services are adapting eco-friendly practices to reduce waste and energy consumption. Using lasers for cutting and engraving results in minimal material wastage and lower energy usage compared to traditional methods.

Conclusion

Laser manufacturing services are at the forefront of technological innovation, offering precise, fast, and versatile solutions for a wide range of industries. With their ability to deliver high-quality results and increase efficiency, laser technologies are shaping the future of manufacturing processes.