Image Source: Google

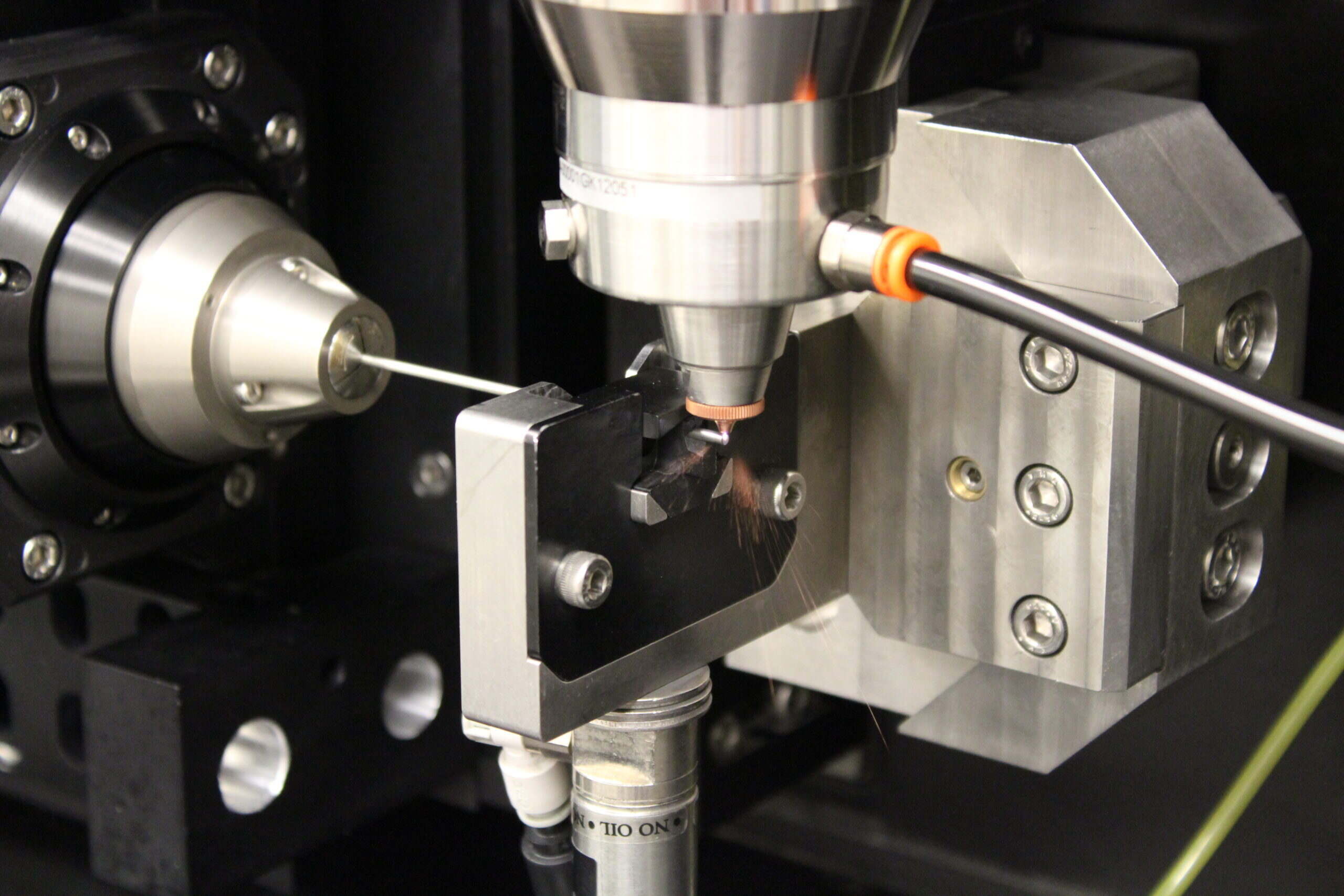

Laser micromachining is a cutting-edge technology that has revolutionized the manufacturing industry by providing precision at a microscopic level. This process involves using a focused laser beam to cut, drill, or engrave materials with incredible accuracy and repeatability. From medical devices to electronics, the applications of laser micromachining are vast and continue to expand as technology advances.

The Fundamentals of Laser Micromachining

Before delving into the world of the best laser micromachining services, it's essential to understand the fundamentals of this technology. Laser micromachining involves the following key components:

Laser Source

- The laser source is the heart of the micromachining system, providing the energy needed to cut through materials.

- Common types of lasers used in micromachining include fiber lasers, diode-pumped lasers, and ultrashort pulse lasers.

Focusing Optics

- Focusing optics help concentrate the laser beam to a specific spot size, ensuring precision and accuracy.

- These optics can be fixed or dynamic, allowing for flexibility in the machining process.

Workpiece Handling System

- The workpiece handling system holds the material in place and moves it with precision during the machining process.

- Advanced systems may include multiple axes of motion for complex machining tasks.

Applications of Laser Micromachining

Laser micromachining services find application in a wide range of industries due to their high precision and versatility. Some common applications include:

Medical Devices

- Manufacturing of stents, catheters, and other surgical instruments that require intricate features.

- Precision cutting of thin materials for implants and medical components.

Electronics

- Micro-drilling of circuit boards for precise placement of components.

- Etching of microstructures for sensors, MEMS devices, and microelectronics.

Aerospace and Defense

- Manufacturing of lightweight components with complex geometries for aircraft and spacecraft.

- Micromachining of materials like titanium and composites for aerospace applications.

Benefits of Laser Micromachining Services

Choosing laser micromachining services offers a multitude of benefits for manufacturers looking to achieve precision and efficiency in their processes. Some key advantages include:

Precision

- Laser micromachining provides unmatched precision at a microscopic level, ensuring high accuracy in the final product.

- Complex geometries and tight tolerances can be achieved with ease using laser technology.

Versatility

- From metals and ceramics to polymers and composites, laser micromachining can process a wide range of materials.

- Various machining tasks, including cutting, drilling, and engraving, can be performed using a single laser system.

Speed and Efficiency

- Laser micromachining is a fast and efficient process, allowing for high throughput and reduced production times.

- The non-contact nature of laser machining minimizes tool wear and material deformation, leading to higher efficiency.

Choosing the Right Laser Micromachining Service Provider

When selecting a laser micromachining service provider for your manufacturing needs, consider the following factors:

Experience and Expertise

- Look for a provider with extensive experience in laser micromachining and a solid track record of delivering quality results.

- Check if the provider has worked on projects similar to yours and has the expertise to meet your specific requirements.

Technology and Equipment

- Ensure that the service provider has state-of-the-art laser systems and cutting-edge technology to handle your project effectively.

- Ask about the type of lasers, focusing optics, and other equipment used by the provider to ensure they meet your needs.

Quality Assurance

- Choose a provider that follows strict quality control measures to ensure the accuracy and consistency of the machined parts.

- Ask about the provider's quality assurance processes, certifications, and inspection methods to guarantee the quality of the final product.

Conclusion

Laser micromachining services offer unparalleled precision and versatility for a wide range of industries, making them an essential technology in modern manufacturing. By understanding the fundamentals of laser micromachining, exploring its applications, and recognizing the benefits it provides, manufacturers can make informed decisions when choosing a service provider. With the right expertise, technology, and quality assurance in place, laser micromachining services can help manufacturers achieve superior results in their production processes.